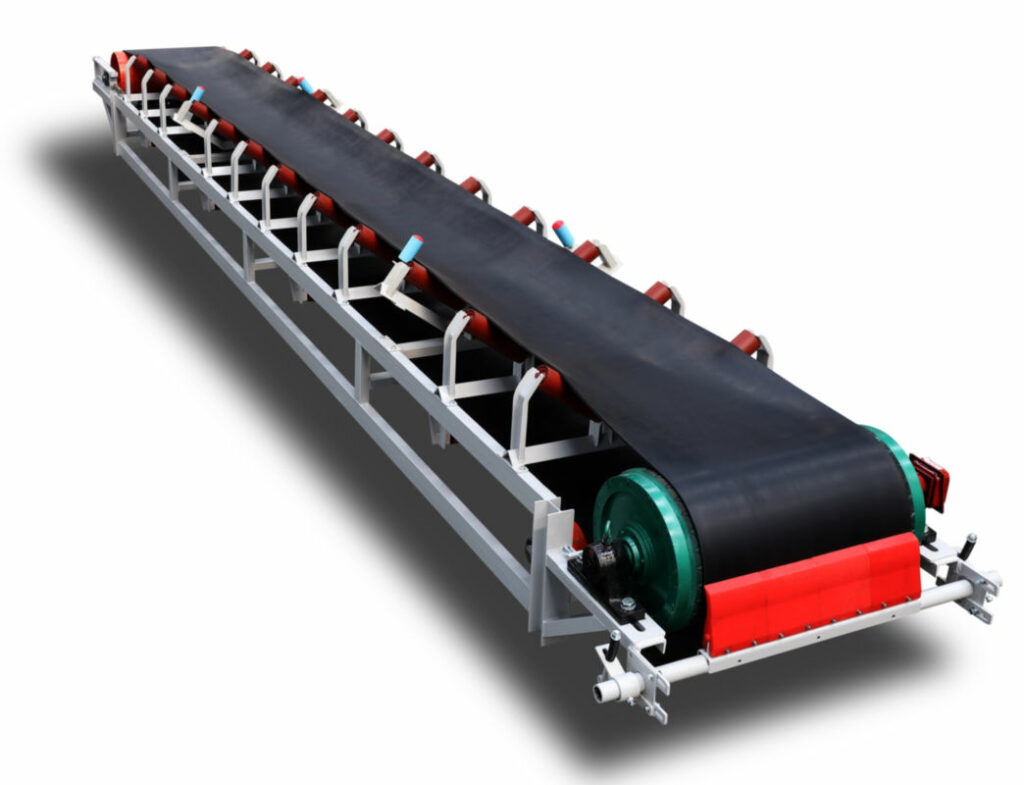

Belt Conveyor

Robust material handling system for reliable transportation of waste materials between processing stages, featuring customizable configurations, durable construction, and seamless integration with sorting systems and processing equipment.

Conveyor Types & Features

Flat Belt Conveyor

Standard configuration for general material transport with smooth, continuous surface.

- Versatile material handling

- Easy cleaning and maintenance

- Available in various belt materials

- Suitable for most applications

Troughed Belt

Belt forms trough shape using side idlers, containing loose or fine materials effectively.

- Increased carrying capacity

- Contains fine materials

- Prevents spillage

- Ideal for bulk materials

Incline/Decline Belt

Angled design for elevation changes with cleats or textured surface to prevent rollback.

- Vertical material transport

- Anti-slip surface options

- Space-efficient design

- Various incline angles

Heavy-Duty Belt

Reinforced construction for abrasive materials and high-impact loading applications.

- Extra-thick belt material

- Reinforced frame structure

- Impact-resistant design

- Extended service life

Key Components

Belt System

- Rubber or PVC belt

- Drive pulley

- Tail pulley

- Tensioning system

Support Structure

- Steel frame

- Roller supports

- Side guards

- Safety covers

Drive System

- Electric motor

- Gearbox reducer

- Belt tracking

- Emergency stop

Custom & Solutions

Tailored to Your Needs

Every waste processing facility has unique requirements. We design and supply belt conveyor systems customized to your specific space constraints, material characteristics, throughput requirements, and integration needs.

Custom Lengths

From compact 3-meter systems to extended 50+ meter conveyors

Variable Widths

Belt widths from 400mm to 2000mm+ to match material volumes

Special Features

Magnetic separators, metal detectors, scales, and more